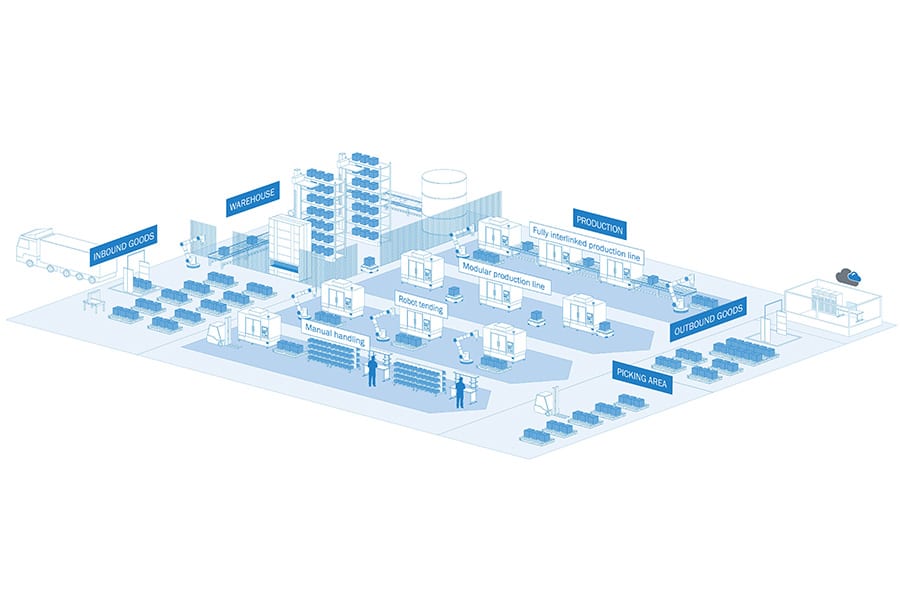

Intra- and production logistics environments further optimized with sensor solutions

Increasing demands are being placed on the logistics environment by emerging trends such as traceability, same-day delivery and smaller packaging. And this at a time when the industry is already facing staff shortages. SICK offers numerous solutions for the intralogistics and production environment. With some four thousand patents, they offer sensor solutions for issues such as: how to scale up the number of shipments without increasing error rates? How do you capitalize on trends without driving up costs? Above all, how do you ensure employee safety when speed is an increasingly important success factor?

Henk Oosterhuis, product manager at SICK: "Some sensor applications are still little known. Like all the possibilities that RFID technology has to offer. With an RFID solution, for example, you can easily locate objects such as boxes and crates, even over long distances. Because this technology works with radio waves, items can be scanned through the packaging. In addition, simultaneous reads or writes can be made to hundreds of tags. So that means you can, for example, count out an entire pallet with a single operation. This technology therefore offers enormous time savings and at the same time significantly reduces the error rate."

Sustainable solution

For almost 80 years, SICK has been designing and manufacturing sensor technology for process, factory and logistics automation. "Because we have been doing this for so long and also work for different target markets, we have created a completely mature product and corresponding volumes. This leads to reliability and durability, also in terms of components." Sensors from SICK can therefore be found worldwide in numerous warehouses, factories and airports.

Obtain master data

Another intelligent solution that Oosterhuis says definitely needs more publicity is the track-and-trace system VML. "This system consists of a light screen frame and evaluation software. It measures transparent, foil-wrapped and even black objects. With that, it forms the basis for an automated and very efficient logistics process." The master data provided by VML is ideal for automatic palletization of transport units or storage based on product size. It also provides reliable sizing for efficient production of secondary packaging.

Positioning

Full traceability is becoming more common. "Visibility within the logistics chain is really something that people are now doing in full swing. By keeping track of where crates and pallets are, you never lose anything. But the status of goods is also becoming increasingly important. Think of track & trace, but also claims that a product has arrived at the customer defectively. By means of data such as photographic material, it can be ascertained exactly with whom the item was still in good condition: the selling party, the carrier, the warehouse or the repair department? So you actually create a kind of vital knowledge layer over your logistics. And we're going further and further into that."

Safe working environment

As a technology and market leader, SICK creates the perfect basis not only for safe and efficient process control, but also for protecting people from accidents. Consider a safe material lock for the machines that wrap pallets in film. When approaching the lock, a safety laser scanner detects the difference between materials and people. Pallets can pass through the safety field unhindered, while when a person enters, the machine stops safely.

Oosterhuis: "Anyone running into these or other dilemmas is cordially invited to enter into a non-binding discussion with SICK. We offer a solution for every process component in logistics, whether in the areas of detection, identification, positioning, measurement and security."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met SICK.

Contact opnemen

Contact opnemen