QuickBox Fulfillment and Inther Group complete special warehouse automation project

Early this year, Inther Group began automating QuickBox Fulfillment's distribution center in Atlanta, USA. For this, various intralogistics technologies, including an A-Frame, Automated Guided Vehicles (AGVs) and Autobaggers, were integrated in a manner unique to the intralogistics industry. The goal was to have the fully automated system fully "up and running" before Black Friday, the absolute peak season for QuickBox. For this, Inther Group succeeded (once again) with flying colors.

Unique combination of system integration

The QuickBox distribution center in Atlanta was equipped with a fully automated logistics system, with a hybrid integration of several types of intralogistics technologies never before realized: the Inther A-frame with dual filling station drops products onto AGVs. These then distribute most of the orders to about four Autobag packaging machines, after which they are sorted. Thus, about 70% of e-commerce orders are picked, packed and sorted fully automatically. The remaining orders (mainly slowmovers with a size too large for the A-Frame) are packed manually via an Inther pick-by-light system. The only thing left for QuickBox to focus on is refilling the A-Frame. The rest of the process is fully automated by Inther.

Martijn Herder - CEO at Inther Group - explains the project: "QuickBox themselves wanted an A-Frame for their Atlanta distribution center in conjunction with automatic order packing with Autobag packaging systems. The A-Frame guarantees the highest possible productivity and optimal material flow for rapid processing of complex orders, even at peak loads. With features such as continuous stock monitoring, real-time video recording and product heat mapping, orders are 100% processed correctly. To automatically transport products from the AFrame to four Autobag packaging machines, Tompkins' AGVs eventually came into the picture. The uniqueness of this system is the automation of the entire intralogistics process, leaving QuickBox to concentrate solely on refilling the A-Frame. This makes it interesting even for fast runners. To my knowledge, this combination of technologies with A-Frame, AGVs and Autobaggers has not been realized anywhere else like it has been here before."

QuickBox itself also looks back on the project with a good feeling: "It is not often that you can be part of a project that is the first in the world. The Inther team has been a very professional and flexible partner in bringing about this unique and exciting automation project within a tight timeframe.", says Shaun Sutherland, Vice President of Implementation & Innovation at QuickBox Fulfillment.

The system

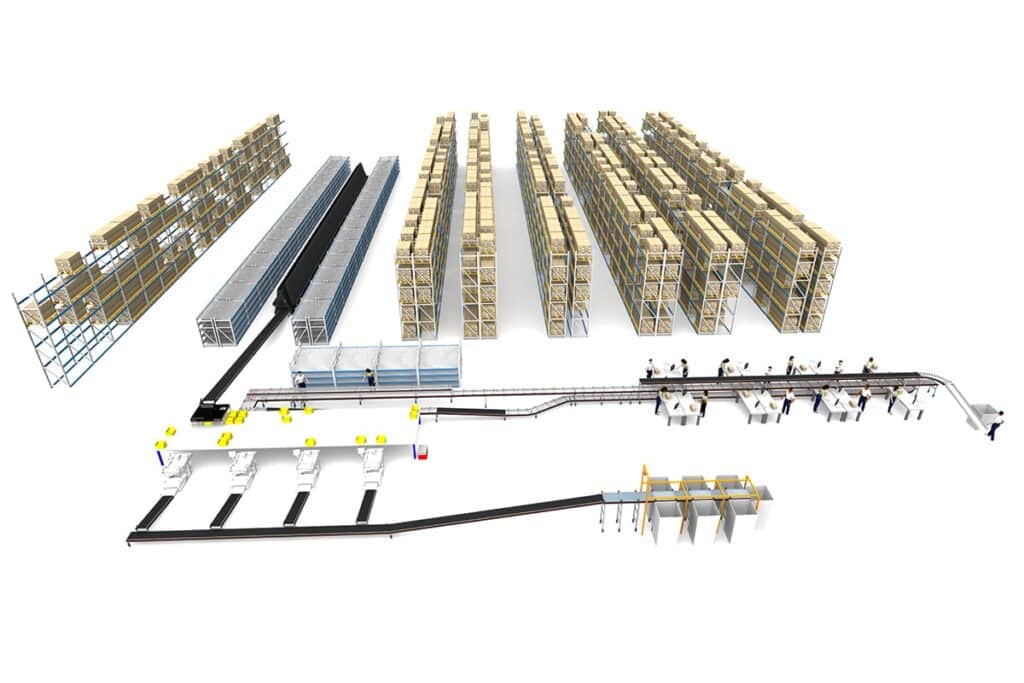

The Inther system includes the following components:

' A-frame (13 modules) with Dual filling station and Puma (measuring unit, which automatically checks stock levels and refills)

' 125-meter conveyors from Inther Conveyor Equipment

' Tompkins tSort solution with 25 AGVs

' 4 Autobag packaging machines

' 3 Modsort units as shipping sorter

' 2 Pick-by-Light workstations

' 14 packaging workstations

About QuickBox

QuickBox Fulfillment, with five distribution centers present throughout the United States, provides a wide range of third-party logistics services (3PL) for e-commerce and multichannel retailers. The e-commerce distribution center in Atlanta is used to store and deliver Pura products (intelligent consumer fragrance diffusion systems and refills).

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Inther Group B.V..

Contact opnemen

Contact opnemen