Institute offers total solution to reduce safety risks in warehouses

Safety Institute Netherlands (VI-Netherlands) is a total supplier of warehouse and safety solutions. They offer unique combinations of products and services, combined with high-quality service and flexibility. These include the supply, inspection and repair of warehouse racking, the installation of markings and lines, the supply of safety products, location identification and employee training. But their services also include the preparation of a traffic plan and company emergency plan. In addition, they provide Risk Inventories & Evaluations with a corresponding plan of action. A safe warehouse begins at Vi-Nederland.

Jan Dücker, Safety Consultant at VI-Netherlands: "In our opinion, the importance of a safe warehouse lies with both the employer and the employee. After all, it is always about the safety of people and they are indispensable in the whole process. Employees are looking more and more critically at their working environment. In addition to making sure they are good employers, business owners must comply with laws and regulations to provide a safe working environment for their employees.

Dücker continues: "We offer the right expertise for every project. Legislation is not always black and white and therefore often open to interpretation. That makes it difficult for entrepreneurs. We help organizations with this process. And the fact that VI-Netherlands can do its bit for safety is of course fantastic!"

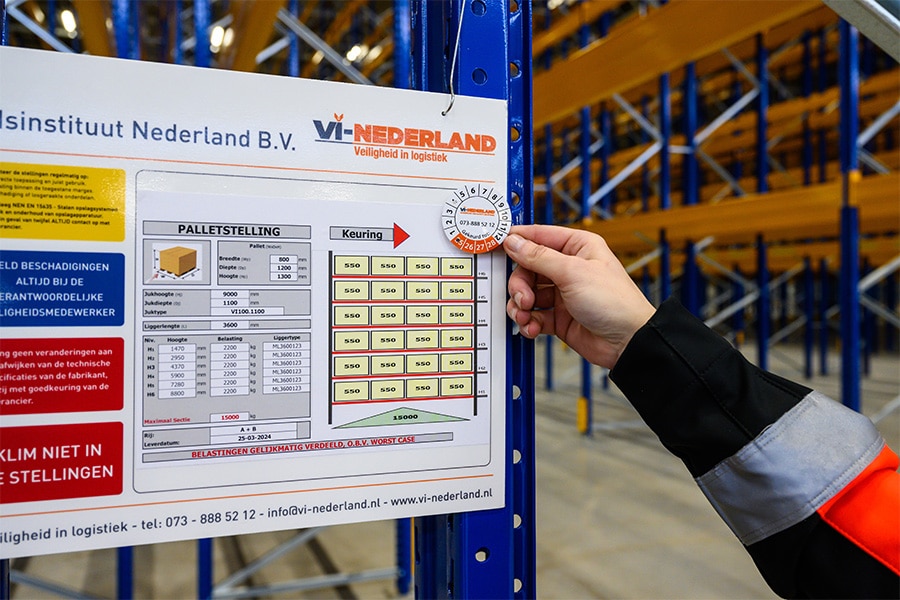

Growth warehouse inspections

"There are several reasons to have warehouse racking inspected by Vi-Netherlands. Not only is safety very important but also proper assembly and use. In a comprehensive report, our experienced inspectors provide the entrepreneur with transparency, pragmatic solutions and expertise. They are trained to assess the entire situation and not just the racking. We see by the growth in the number of inspections that many entrepreneurs realize the importance of our inspection and expertise."

Distinctiveness

There are obviously more companies that focus on security, so what sets VI-Netherlands apart? "During the first contact, the customer will immediately notice that our professionals know exactly what they are talking about. The basis of our input consists of thorough product knowledge, solution orientation and a pragmatic approach. Upon order confirmation, each project is carefully worked out and prepared. We make sure our employees are informed in advance so they know what is expected of them, materials are ready on time and the entire communication flow and schedule are correct. Our project manager goes over the details with the site manager so there are no surprises during the work and upon completion. That's what we mean by working efficiently and safely."

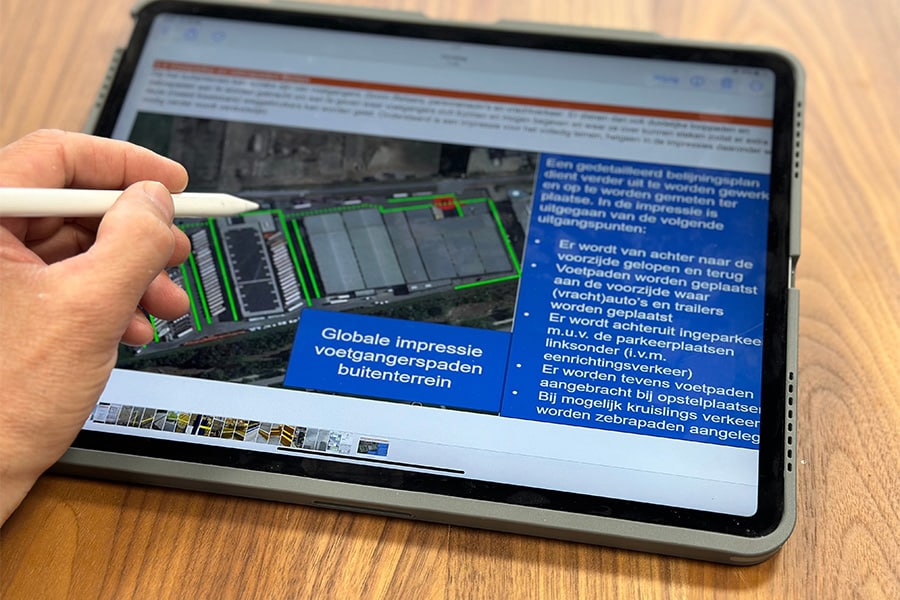

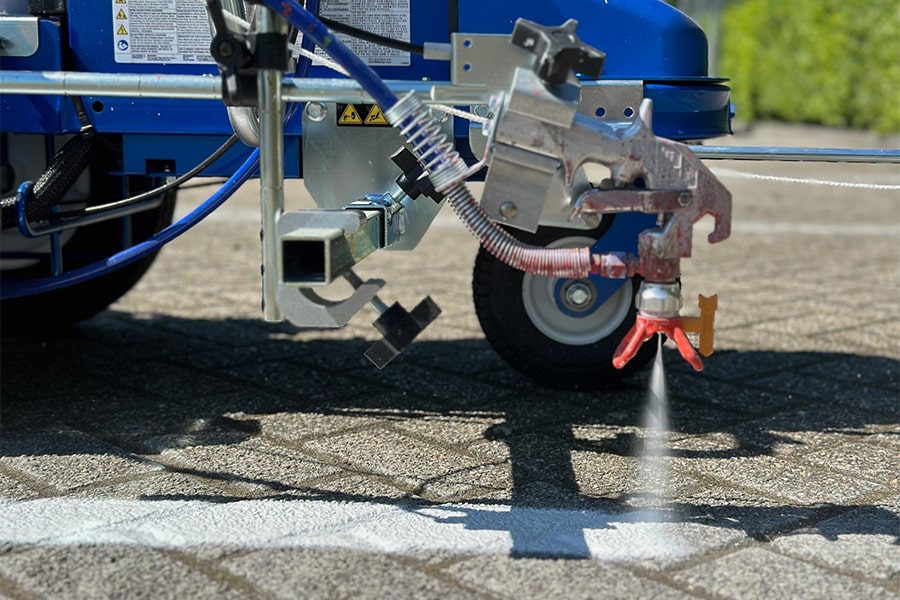

Experience with projects

"Every week we carry out various projects. Not only for repair but also for marking and lineation. We always think along actively. For example, the purpose of marking and lining is to provide more structure to the site, providing predictability and thus a safer environment. However, we often see that the lineation, if there is any, is not properly aligned with business processes. This is a missed opportunity! We do not just apply lines, but do so with a clear underlying plan. This can include a lineation or traffic plan. We ask about the processes, means of transport and make flows transparent. If we see that there is room for improvement, we of course indicate this. We then provide premium products for the marking and lining, in the form of V-SIGN© and V-MARK©, for durable solutions in harsh conditions."