Enhanced Dig Assist features set the tone for digging accuracy

With the addition of a host of new features, Dig Assist raises the bar even higher, maximizing excavation productivity, efficiency and safety.

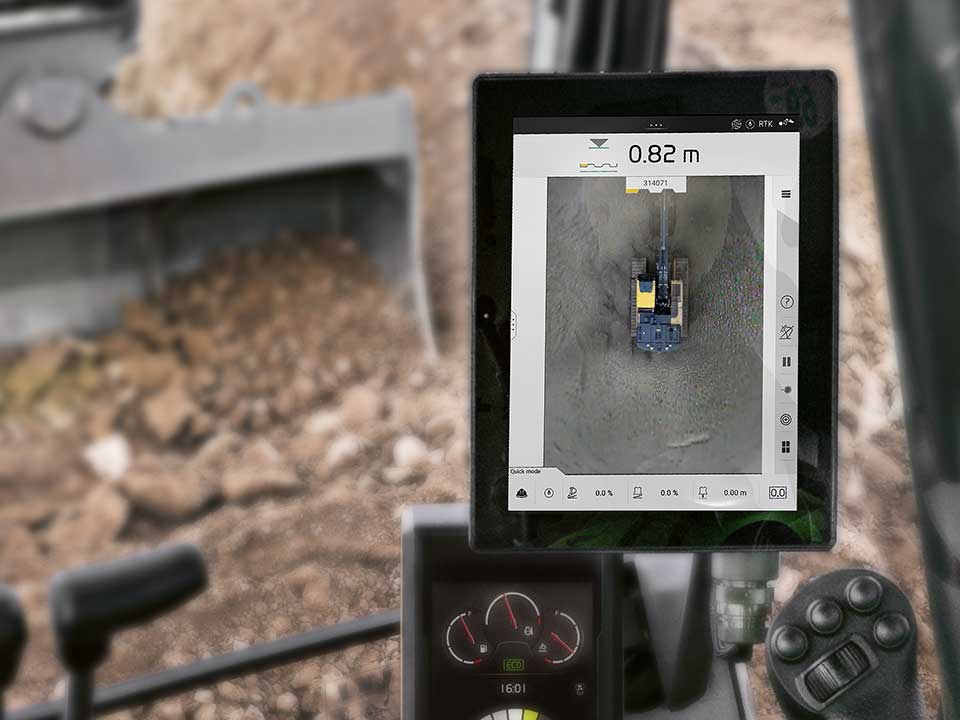

Operating a machine will always be a skilled job, but it doesn't hurt to improve the performance of your best operators as well. Dig Assist from Volvo CE exploits the full productivity potential of a hydraulic excavator. Using the Volvo Co-Pilot tablet in the cab, the operator can quickly and independently manage all excavation tasks - whether it's leveling sites, digging trenches, leveling slopes or creating site profiles. Dig Assist eliminates the need to manually mark a site and check depths and slopes, also increasing safety and ease of use.

Overview: Machine Control

Dig Assist is available with 2D, In-Field Design and 3D applications so the operator can create a detailed excavation plan from the comfort of his cab.

The longstanding 2D application is designed for leveling terrains and profiling slopes. This option uses real-time data to clearly indicate to operators when set depths or slope angles have been reached.

In-Field Design simplifies time-consuming work by allowing operators to switch from a paper drawing to a digital excavation model in minutes. This option uses GNSS and RTK navigation technology and provides centimeter-level accuracy for jobs such as trenching, preparing driveways or pools and laying foundations. Work data can also be stored in the Volvo Co-Pilot so that the task can be resumed at a later time if necessary.

The 3D application is the ideal choice for larger and more complex infrastructure projects. Topcon 3D-MC and Trimble Earthworks for Dig Assist offer full three-dimensional functionality so designs can be uploaded directly into the Volvo Co-Pilot screen. The ability to offer both solutions is unique to Volvo, just import the project file and you are good to go.

Volvo Active Control

Do the same job day after day and achieve the same consistent results with Volvo Active Control. First introduced in 2019, this machine control system guides the operator through functions to automate the digging process and achieve perfect results - up to 45% faster than traditional grading. This feature is also controlled via the Volvo Co-Pilot display in the cab. Volvo Active Control is an electrically controlled solution, combined with Volvo's electro-hydraulic control system and Dig Assist software platform.

Leveling tasks become much easier thanks to the semi-automatic leveling functions of the Dig Assist application. Once the required parameters for the task have been entered into the system, the excavator automatically adjusts the boom, bucket movements and slope angle and depth to produce accurate excavations. This involves following the desired shape and delivering exactly the right slope angle - in addition, this is now compatible with 3D (Topcon).

By setting limit ranges, operators can also automatically stop the swing at a certain angle to facilitate truck digging and loading. And when working in tight areas, operators can adjust the height and swing angle of the boom and bucket to avoid obstacles on the sides or above the machine.

New integrated weighing system

Loading the optimum amount of material requires seamless organization. Volvo CE's dynamic weighing system (On-Board Weighing) provides real-time visibility into the bucket's load so that the driver always meets his loading goals. The system prevents over- and under-loading and ensures that each truck meets road regulations while fully loaded. Drivers can set goals, including a target trip meter load or the desired target load for a truck. Features such as load tare, unlock current load and ignore last bucket load ensure optimum accuracy. And the load zone selector allows drivers to determine the position of the load zone so that loads can be prevented from being skipped or added incorrectly. The system also counts all bins unloaded in the preset loading zone.

Handy supplies

Volvo Co-Pilot is pre-installed with applications that make the operator's life easier. Weather Forecast, Calculator and Notes are new applications that work in the same way as on a smartphone. Dig Assist is also compatible with a range of smart tools that get even more out of the excavator, such as Volvo Smart View - which gives operators a 360° all-round camera view from a bird's eye view. The image can be displayed on the Volvo Co-Pilot screen or on the machine's display. In addition, Dig Assist can be used with multiple attachments, including tilt rotators, tilt buckets and quick couplers - all of which can be easily built into the implements.

In addition, Dig Assist can be updated to the latest software versions without the intervention of an on-site service technician thanks to a new live update function, just like on a cell phone. The new version allows remote support directly from the cab via a help button on the Volvo Co-Pilot.