Modular mesh wall system provides flexible security

Optimal security in logistics centers

Axelent is an originally Swedish manufacturer of mesh wall systems for security and separation systems in industry, warehouse and construction. In the logistics world, it is one of the market leaders in safe shielding of a warehouse or warehouse. Due to robotization and automation, machine protection is becoming increasingly important, says sales manager Renik Retoré. Axelent's unique modular click system makes modifications or expansion a piece of cake.

"All the items you see on our website are of our own making," says Renik Retoré, sales manager for the Netherlands on behalf of Axelent Benelux. Retoré explains that Axelent produces both freestanding mesh wall systems for warehouses and mesh walls that can be hung on pallet racks and thus serve as fall-through protection. "Fall protection is the pillar in which Axelent started and became big," says Retoré. "The other big pillar is machine protection. And that is also the product group for which we develop the most accessories and invest the most R&D time."

Physically separating

Because in industry - and therefore also in logistics - more and more fully automated machines that can run autonomously are being used. Think of robots, conveyor belts, a sawing machine, packaging machines or a pallet handler. "All those machines are covered by the Machinery Directive," Retoré explains. "And that makes a number of recommendations to get a machine inspected in such a way that people can work with it safely. And one of those ways is to physically separate the danger zone around the machine from the safe zone. Axelent has a solution for that in the form of physical barriers called X-Guard. That is flexible machine protection with smart components that always comply with current guidelines and standards."

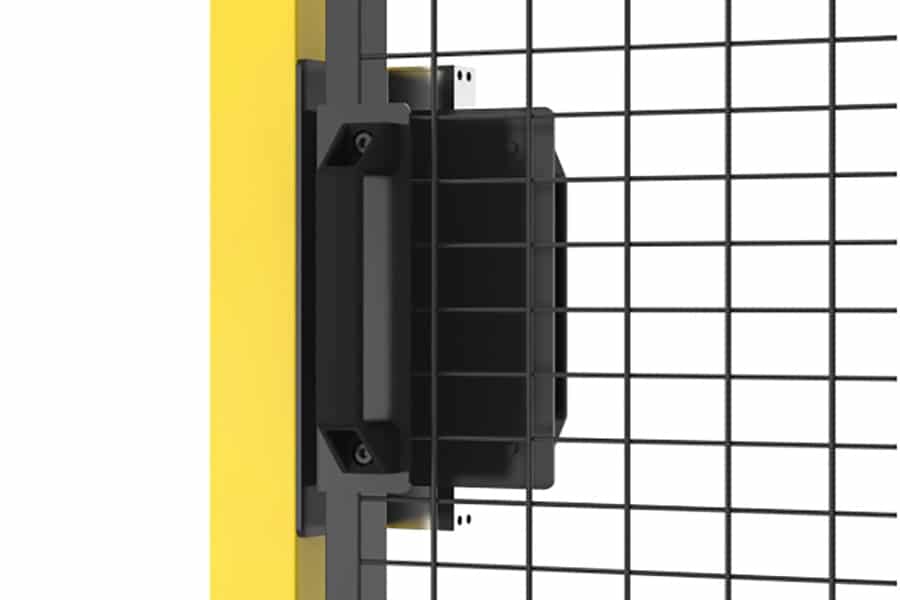

What makes the X-Guard system so unique is the method of fixing by means of a click system. "Our mesh wall systems can therefore be installed, dismantled, moved or expanded extremely quickly and easily as needed," Retoré explains. "Thanks to the click function, it is easy and, above all, quick to install and no other tools or fastening materials are required. Once in place, the panel is simply clicked into the pole. The quick attachment works equally well whether the panel is made of mesh, sheet steel, plastic or round corners. So it is very easy to adjust."

Robotization

Retoré observes that production and logistics are increasingly converging in terms of how they work. "Within the logistics sector, you see more and more robotization and automation. Where in factories and production houses the work of people on an assembly line was already taken over by robots, you are currently seeing a huge catch-up in the logistics sector. In warehouses there are more and more automated pallet trucks and AGVs, Automated Guided Vehicles. For Axelent, this means that two worlds that we served separately in the past are growing closer together. As far as I'm concerned, that makes this time a very exciting period."

And while it may seem that the fewer people walking on a shop floor the less security you need, Axelent says rather the opposite is true. "That may seem logical, but although automated forklifts and AGVs are already well secured with collision sensors and the like, there are still some areas in a warehouse where you don't like people walking around. People become an obstacle in the flow of operations for which these machines are programmed and you don't want that. On the other hand: there may be fewer people on the shop floor, but the number of vehicles actually increases. And more machines on the floor means more maintenance, more updates and more breakdowns that need to be fixed. We see that in those departments, the workforce is actually growing."

Another risk Retoré describes concerns people who are not employed in the warehouse itself, but work for an external maintenance party, for example. "They are less familiar with the risks in such a hall, so for them it is important to secure the environment properly. Although you also don't want your own personnel to accidentally put their hand into a running machine. So security with a mesh wall system is always a sensible solution."

Collision Protection

Over the years, Axelent has evolved from a manufacturer of security products into a partner that thinks along with the construction of production and logistics buildings at an early stage. The latest innovation the company has added to its product portfolio is collision protection. Retoré: "Unlike many competitors, our X-Protect crash protection is made entirely of plastic. This was something new for us, in addition to the steel mesh walls, but we do not shy away from innovation. Combining mesh wall systems with crash protection means that we have a complete system in house that perfectly meets the needs of the market and is also enormously flexible due to its modular design. Everything can be combined with each other and adapted to a new situation at lightning speed."

Made in the Benelux

One innovation that Axelent is very proud of, which was invented in the Benelux, but is now used around the world, is an electronic lock that is mounted in the security doors. "Most of the swing or sliding doors in our mesh wall systems had a normal cylinder lock. We saw that more and more customers liked to see who is in which room. So we developed an electronic lock in Belgium that could be opened with a pass or batch. These locks were so popular that it was decided at headquarters in Sweden to introduce them worldwide. It shows how Axelent is increasingly thinking with its customers and completely unburdening them."

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met AXELENT.

Contact opnemen

Contact opnemen