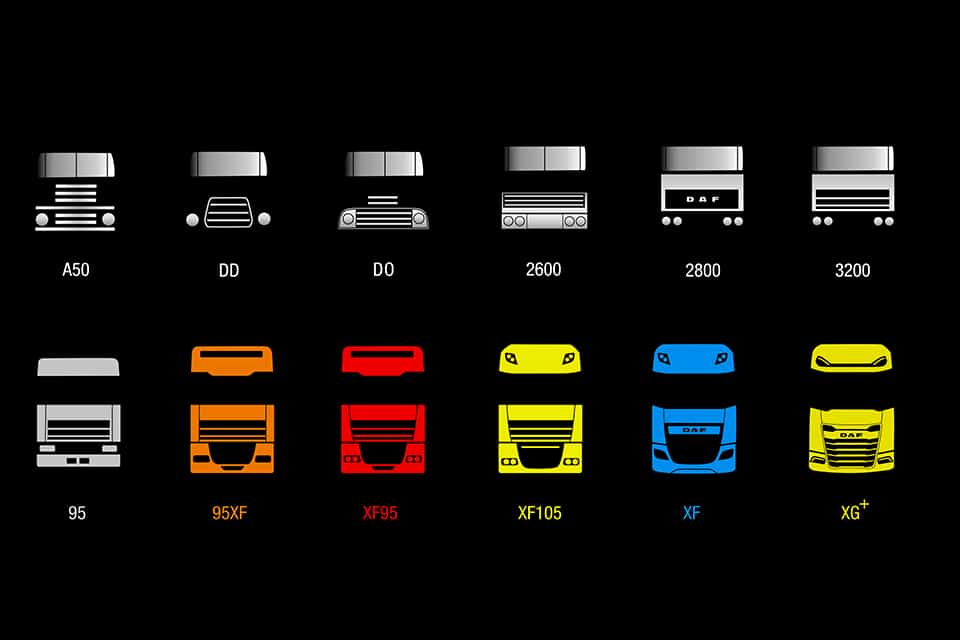

DAF: 75 years of trucks from Eindhoven

Innovation, smart designs and revolutionary technology

DAF Trucks is celebrating 75 years of building trucks this year. A milestone from a long line of highlights driven by innovations, revolutionary technologies and smart designs. Those same building blocks form the foundation for the latest generation of DAF trucks, making them, like their predecessors in their time, the benchmark in efficiency, safety and driver comfort.

The foundation for DAF is laid in 1928. In the early years, Eindhoven knows the company as 'Van Doorne's Machinefabriek'. When Hub and Wim market trailers in the early 1930s, the first contours of today's DAF become visible. Contrary to common practice, the chassis were not riveted but welded - and thus much lighter than usual. The success is great. The machine factory shifts its focus and continues as Van Doorne's Aanhangwagenfabriek; DAF for short.

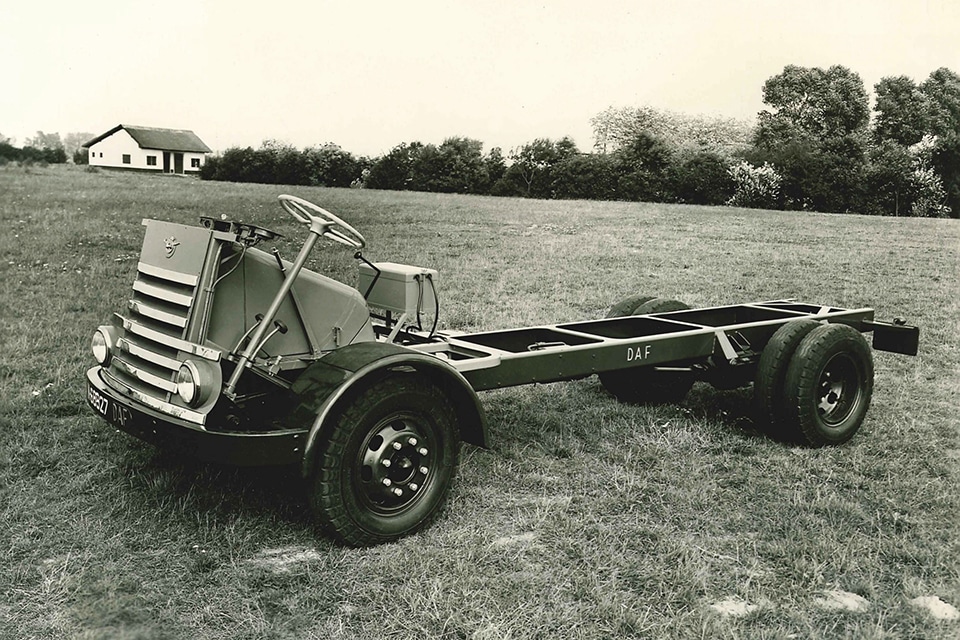

The first truck

When, during the reconstruction of Europe, the demand for transport grows explosively, DAF gears up quickly. A production line for trailers and semi-trailers is set up and at the same time preparations for a truck factory take concrete form. During 1949, the A30 is unveiled. It is a 3-ton truck intended primarily for the patriotic market. The grille is characterized by seven chromed stripes.

Anchored in the streetscape

Just a few months later, the first example rolls out of the factory - soon followed by the A50 (5 tons) and the A60 (6 tons) for heavier work. A van - the 1-ton A10 - sees the light of day in 1950. This was followed by a pickup truck, the A107. The number of models subsequently increased dramatically, including special chassis for dump trucks and garbage trucks as well as a series of military vehicles. DAF quickly developed into a truck brand that became an indispensable part of the street scene.

Incidentally, all trucks then come off the line only as chassis-with-engine-and-grille. The construction of cabs is left to coachbuilders. This changes in 1953, when DAF starts assembling its own cabs. In 1955, the factory celebrates the production of the 10,000th chassis. A celebration that is given extra splendor by an order from the Dutch army for 3,600 vehicles. Shortly thereafter, DAF also begins developing and building its own (diesel) engines. DAF will be the first to fit - for extra power and higher efficiency - a turbocharger to its power units.

International transport

In 1957, DAF presents the DO; a characteristically drawn truck with a 10-ton rear axle specially developed for this series. It makes the DO a truck ideally suited for both heavy and international transport, which has begun a tentative advance. The second generation of the DO can even be equipped with a makeshift bed - a novelty.

In the early 1960s, the Dutch truck maker surprised again, this time with the DAF 2600. A truck that, even more than the DO, is aimed at international transport. The cab is revolutionary. Its angular shape maximizes the living space - and thus the comfort - of the driver, who is sometimes away from home for weeks at a time. The cab accommodates a fixed bed, and an upper bed is even available. The large windows provide light as well as unprecedented all-round visibility, contributing to safety. The 2600 series will go down in the books as "the mother of international transport.

Trendsetter

In 1970, DAF brings out the F1600 - F2200 series. The vehicles are equipped with a tilting cab, making DAF one of the first. The advantages of the tilting cab are enormous. The mechanic can perform maintenance much easier - and thus better and faster - while the driver gets a much quieter workplace because the engine is encapsulated by the cab.

In 1973, the revolutionary 2600 gave way to the all-new 2800 (and later 3300 and 3600). This has not one but even two beds and, thanks to its enormous comfort, is immediately the truck for long-distance travel. DAF was also the first truck manufacturer to launch the turbo-intercooler for more torque, more power and lower fuel consumption.

Super SpaceCab

In the 1980s, DAF gives long-distance and heavy transport a new impetus with the DAF 95, which can even be equipped with an extra-high roof for unparalleled driver comfort: the SpaceCab. It will even be followed by a Super SpaceCab, the superlative in space and luxury. For regional and national transport, DAF presents the DAF 65/75/85.

Leading the way in sustainability

This series of vehicles - like their later successors, the CF and XF - makes a name for itself within Europe, and increasingly beyond. The same is true of the new LF series, launched at the turn of the century. The vehicle is intended for regional a local distribution. DAF will even be the first to market a hybrid truck in 2010. This LF Hybrid reduces fuel consumption and CO2 emissions by about 20 percent by using the electric motor in urban areas. The LF Hybrid shows that DAF is leading the way in making road transport more sustainable. The latter is powerfully underscored by the DAF CF Electric. It is, in 2018, the first all-electric truck from a European truck manufacturer.

New Generation DAF

During those years, the European Union is working on new regulations for truck sizes and weights. When these come into effect in late 2020, DAF will be the first truck manufacturer ready for them. As a result, the New Generation DAF trucks to be unveiled in 2021 will be as revolutionary as the illustrious DO, 2600, 2800 and XF were in their day.

Regulations give truck manufacturers leeway to make cabs slightly longer, if that extra length benefits the environment, safety and the man or woman behind the wheel. The New Generation DAF trucks therefore offer significantly more space for the driver, are significantly more economical due to their streamline, and - with their extremely deep-set windows and intelligent camera systems - are also designed to contribute maximally to road safety. DAF has won the prestigious "International Truck of the Year Award" twice in a row with the XF, XG and XG+ for heavy-duty and long-haul transport, as well as the XD series (for national and regional distribution).

The XD and XF will also be available with an all-electric powertrain, enabling them to travel up to 500 kilometers emission-free on a single charge. The XD and XF Electric will be built in the Electric Truck Assembly Line, a the completely new production line that will come into operation in 2023 at DAF's factory site in Eindhoven. The urban distribution variant - the New Generation DAF XB - will also come with an all-electric version from DAF, produced at Leyland Trucks in Britain.

Ready for the future

DAF is in excellent shape for the future. Not only because of the new generation of vehicles, but also because they are working hard on innovative transport solutions. For example, DAF is working on zero emission hydrogen engines that emit only water vapor. At the same time, within parent company PACCAR, practical tests are being conducted with ultra-clean fuel cell technology and the development of electric drivelines is certainly not standing still.

DAF trucks are sold all over the world - from Africa to Oceania. From South America - where DAF even has its own factory in Brazil - to Asia. And in Europe, of course. Last year, a record 69,800 trucks were built there. DAF customers rely not only on the vehicles, but also on the broad portfolio of support services. From an international breakdown service, first-class parts supply and financial services to fast chargers for electric trucks and even the installation of self-supporting local energy grids. Transportation efficiency is about more than just high tech trucks.

Real DAFs remained

"Hub and Wim van Doorne would not believe their eyes if they saw the 2024 products," knows Harald Seidel, President and CEO of DAF Trucks. "At the same time, they would note with satisfaction that our trucks are real DAFs: innovative, high quality and developed for the highest efficiency, maximum driver comfort and unparalleled safety. They would be proud. Just as proud as I am of the past, the present and our plans for the future."