Innovation, sustainability and performance: new Linde E and Xi

Innovation and sustainability are at the heart of the world of intralogistics, and Linde Material Handling confirms its leadership with the launch of two brand new forklift models: the Linde E and Linde Xi. Under the watchful eye of press, experts and partners, the latest developments were presented on November 4 and 5 in Aschaffenburg, Germany, focusing on powerful performance, ergonomics, safety and automation.

On Monday afternoon, guests arrived at the Seehotel in Niedernberg, a quiet location that provided the perfect setting for this exclusive event. After a leisurely lunch and a moment to freshen up, the group was taken by shuttle to the Linde factory in Aschaffenburg, where the tone was immediately set: Linde's drive for innovation goes hand in hand with their commitment to a safe, efficient and partially automated future.

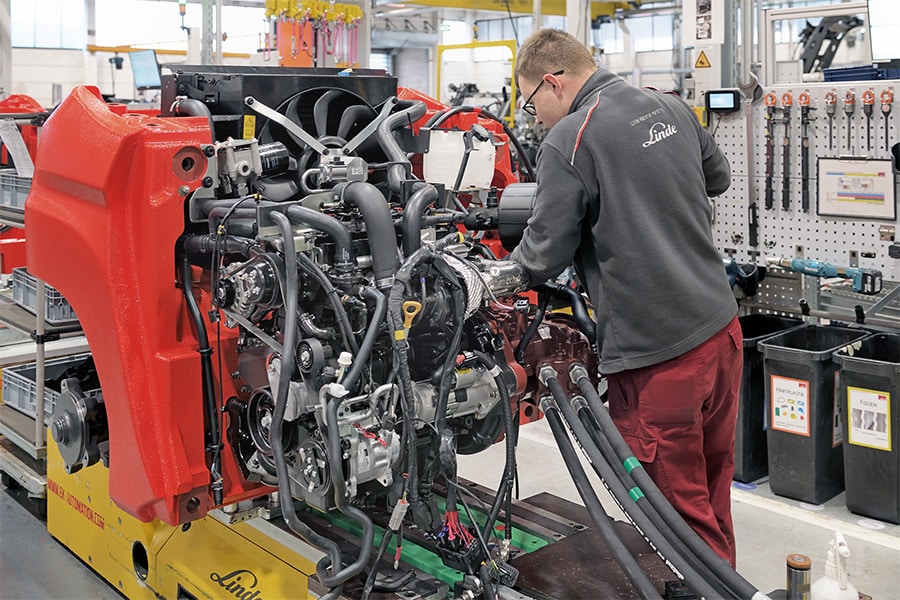

Impressive journey through the Linde factory

A first highlight was the extensive tour of the Linde factory, where guests not only got a look behind the scenes, but also got into direct contact with the people behind the technology. Linde's product and solution specialists talked about the latest innovations, including safety features, digitalization and automation. The latter in particular is taking off. The fully automated and unmanned AGVs were therefore indispensable. Also more than impressive were the house-high robots that assembled certain parts of the forklifts. More than 200 forklifts a day go out the door here, including 30% 'fully customized' ...

The sessions focused on practical solutions to today's logistics challenges. The safety systems that distinguish Linde's products, such as the Linde Safety Guard and the Linde Reverse Assist Camera, were explained. The latter uses AI to detect people and objects and can even adjust the truck's speed to avoid collisions. Thus, Linde emphasized the crucial role of technology to minimize accidents and create a safe workplace.

High performance, low impact

After an early breakfast on Tuesday, the company left for Linde headquarters, where the press conference took place. Ulrike Just (Executive Vice President Sales & Service Linde MH EMEA), Pau Carrere (Vice President Sales & Service Business Dev. Linde MH EMEA) and Torsten Rochelmeyer (Senior Director Strategy & Solution Portfolio Linde MH GmbH) welcomed everyone. Just emphasized Linde's brand values - performance, passion and technology leadership - which are anchored in every new product. The official launch then took place at the Linde Experience Hub, where the new Linde E and Linde Xi models were unveiled. These electric forklifts specifically focus on high performance in challenging environments and meet the growing demand for powerful, energy-efficient and versatile solutions in intralogistics.

The Linde Xi models feature an integrated lithium-ion battery, resulting in more power and a long service life. The Linde E models, on the other hand, offer flexibility with the ability to switch between lead-acid and lithium-ion batteries. In addition, they are prepared for fuel cell technology, making these trucks ready for the future.

The trucks are designed for a wide range of applications - from beverage stores and distribution centers to the construction and metal industries. Their robust design and fast lifting and lowering speeds allow them to operate without difficulty in demanding environments, such as extreme temperatures, dust and dirt.

Comfort and productivity in one

Linde's new trucks are more than just powerhouses; they are also designed with the operator in mind. Cab ergonomics offer added comfort, with increased foot space and optional air conditioning. In addition, the innovative damping system reduces shock and vibration, lowering the driver's physical strain and increasing overall productivity.

Another notable feature is the "Linde Steer Control" system, where the traditional steering wheel gives way to a mini-wheel or joystick, ensuring precise control with minimal movement. This intuitive design focuses on driver well-being and efficiency and responds to the growing labor shortage in the logistics sector.

With MyLinde, every forklift becomes smarter

Much of the event was dedicated to Linde's vision of automation and safety. Linde positions itself as a total "material handling" solution, with a full ecosystem of software, energy solutions and automation systems integrated with their vehicles. In addition to the current lineup, Linde announced that they will soon introduce five new automated vehicles, an impressive step toward a more automated future in intralogistics.

On the safety front, it was clear that Linde is doing everything possible to minimize risks for drivers. Using AI and sensor technology, their vehicles can distinguish people and objects and react automatically to prevent accidents. The ultimate goal? An accident-free workplace, which Linde says is at the heart of their "Vision Zero" safety program.

In addition, digitalization is playing an increasing role in their strategy. With the introduction of MyLinde, a customer interaction platform, users will soon be able to communicate directly with their vehicles, generate reports and monitor fleet performance. This is all part of the ambitious company's commitment to enable predictive maintenance and software updates via the cloud, increasing efficiency for their customers.

New standard in intralogistics

The press event in Aschaffenburg proved that Linde Material Handling is not only keeping up with trends, but actively shaping them. With the new Linde E and Linde Xi, the company has taken a clear step towards sustainable, safe and fully automated solutions. These were two inspiring days in which Linde's commitment to innovation, ergonomics and customer focus was reflected in every detail. For everyone involved in intralogistics, the latest generation of forklifts offers a glimpse of what the future holds: a more efficient, safer and greener workplace where technology and people are central.

Heeft u vragen over dit artikel, project of product?

Neem dan rechtstreeks contact op met Motrac Internal Transport.

Contact opnemen

Contact opnemen